Service advantage

Weprovide comprehensive technical support, installation service on site andtechnical training for our customers.To guarantee customers to obtain thegreatest value from our product and service we have first-class after saleservice: quick response in 12 hours and on-site maintenance in 48 hours when receivingfailure notice in China.

Concept of innovation combines technology and flexibleengineering into technical solution. From project startup to manufacturing,from inspection and delivery to installation on site we have a complete ordermanagement process to ensure that each point is followed and examined. Wedemand exactness in details and constantly provide the most improved technicalsupport and after sale service to ensure our equipment efficient operation,lower production cost and make customer more competitive.

Heatking has a high quality technical team who lay Heatkingleader’s foudation in induction heating field and make our quality reach theadvanced international standard. To turn the newest technology in to realproductivities we signed a lot of technology development & cooperationagreement with a few famous universities like Shanghai University, ShanghaiJiaotong University, Nanjing University of Science and Technology,etc.

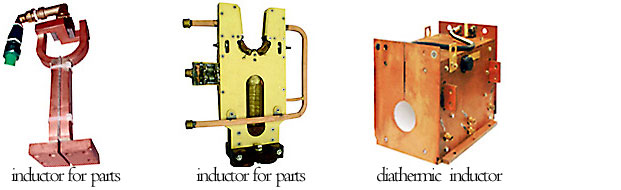

Inductoris the core of machine and Heatking can develop inductor according to customer’srequirement. Quality is the life of enterprise. From the material purchase tomachine manufacturing and assembly, Heatking has a strict quality managementsystem. To guarantee quality we specially developed a processing parametermonitoring system which can adjust parameters timely so as to control theprocessed part’s quality precisely. We’re equipped with professional inspectiondevices, such as metallographic cutting machine, grinding and polishing machineand metallographic microscope to check the parts that are heated. All of the systems are tested in housebefore they are shipped to customers.

Homemade inductor

Accurate detection system

Advanced monitoring system

Processing parametermonitoring system is based on the Siemens 677C energy monitoring computeroperating system and it can supervise the output energy, voltage, quenchantflow, water temperature and working condition via signal collecting system,signal processing system and signal feedback system in order to confirm the quenchedparts are qualified or not. Or it tell generator to stop heating when processmeets the requirement to ensure equipment can make qualified parts undervarious working conditions. The system uses standard keyboard operation, canpre-set time, current, voltage and energy, show various heating curves andrelated index at the same time. This system can reserve the processing parametersfor all kinds of parts, record the various production data (like productiontime, shift, quantity, etc.) for check or printing in the future. The interfacehas indication instrument, history record and staff with different position login situation.